protoTRAC®

Easy ECU Prototyping

Prototyping Electronic Control Units (ECUs) are used to implement control algorithms at the development and test phases. They are prevalent in automotive fields but can be applied in many other areas.

protoTRAC® prototyping ECUs were created to satisfy the need for powerful, full-featured units that are easy to use and don’t have the associated software cost of many other top-end units.

protoTRAC® ECUs are set up using LabVIEW™ control software. LabVIEW™ allows control strategies to be set up in a graphical way rather than writing code.

Products

protoTRAC® ECU400

Key features:

- On board power output capability:

- 4 x 10 A low side drive channels, PWM capable

- 4 x 5 A low side drive channels, PWM capable

- On board digital I/O:

- 16 x digital input channels

- 16 x digital output channels

- On board analogue I/O:

- 14 x analogue input channels

- 4 x analogue output channels

- On board CAN-bus:

- 2 x high speed CAN channels

- Optional H-bridge driver board for DC motor direction control:

- 5 x 10 A H-bridge channels

- Connection to PC via standard RJ-45 patch cable

- Programmed with National Instruments LabVIEW™ software

- Flexible data logging capabilities

- Wide power supply voltage range

- Power supply connections via standard terminal posts

- External circuit connections via zero insertion force connector

Technical Specifications:

| Description |

Quantity |

Specification |

Notes |

| Processor |

1 |

400 MHz |

|

| Non-volatile RAM |

256 Mb |

|

|

| System RAM |

128 Mb |

|

|

| FPGA |

2 M Gate |

46080 logic cells

720 kbits RAM |

|

| LAN communication port |

2 |

10/100 Mb/s ethernet |

|

| Power Supply Voltage |

12 - 24 V DC

9 - 36 V DC |

Nominal

MIN - MAX |

| ECU Current Drain |

2 A

3 A |

MAX

Fused |

| Total Equipment Current Drain |

50 A

50 A |

MAX

Circuit Breaker |

| +VE Voltage Source |

16 |

5 A per channel |

Nominal load rating |

| CAN channels |

2 |

HS-CAN |

up to 1 Mb/s |

| Analogue Inputs |

14 |

±10 V, ±5 V, ±1 V, ±0.2 V |

Single Ended |

| Analogue Outputs |

4 |

±10 V DC @ 3 mA MAX |

Single Ended |

Digital Inputs

PWM capable) |

16 |

LO < 0.8 V, HI > 3.3 V

0V MIN - 1.5 V MAX

2.7V MIN - 35V MAX |

Nominal

LO

HI |

Digital Outputs

(PWM capable) |

16 |

LO = 0 V, HI = 12 V

25 mA drive current |

Nominal

MAX |

Power Low Side Drives

(PWM capable) |

4 |

10 A

9 A current limit

*

* |

Nominal load rating

Hardware set

Requires pins to be wired

in pairs if channel load > 5 A |

Power Low Side Drives

(PWM capable) |

4 |

5 A

4.5 A current limit |

Nominal load rating

Hardware set |

| Aux power output |

4 |

5V

100 mA drive current |

Nominal

MAX |

Applications

protoTRAC® ECU400:

The range of integrated I/Os in the protoTRAC® ECU400 helps in the spread of applications it can be used in. It is well suited to automotive drivetrain situations where CANbus signals are being used to dictate actions within the drive but it could equally well be used in other areas.

Data Logging:

Data logging is user defined within LabVIEW™ and is therefore completely flexible. Logging may be started and stopped via the user interface, or perhaps via a hardwired switch. Data is logged to the ECU internal memory and may be downloaded to any computer via the ethernet port using file transfer protocol.

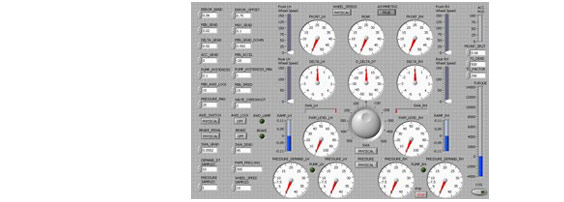

Control System User Interface:

One particularly useful aspect of the LabVIEW™ programming software is the interactive user interface, which may be accessed remotely from any computer with an ethernet port to monitor the system, log data and even change control parameters if permitted, using only a web browser.

Above you can see a protoTRAC® ECU400 controlling drivetrain hydraulic valves in an AWD system. This replaced an existing prototyping ECU plus external interfacing hardware. The protoTRAC® ECU400 was set up with a web interface and underwent extensive testing including cold climate work where the customer was able to test various configurations and has led to successful implementation of a new generation of system.

Services

Beyond standard support we can offer LabVIEW™ programming. You might have got a good idea what your algorithm should be and you’d to start your project with a system set up with your initial algorithm and interface. We can produce a system ready for you to plug in and start testing parameters; one with an implementation of your algorithm that you can build upon.

We can agree on a specification including the interface to your sensors, bus (probably CAN) and required cycle time and we’ll set up your system ready to go.

The protoTRAC ECU can behave as a web server so we can set up a web interface that you can access from any web enabled computer and use this as your means of changing parameters and monitoring/logging data without the need for any additional software (not even LabVIEW™).

The above image shows a comprehensive screen monitoring a vehicle’s CAN-bus and sensors. The interface has the optional ability to change parameters on the fly. You can use such an interface on as many installations as you want without any additional charges - a useful cost saving when you want to work on, or test, more than one installation.

Programming

We need to assess programming jobs individually, but generally they’re costed on the basis of £50/hr but give us a call to discuss details.